추천 블로그

주요 솔루션

추천 이벤트

THE BATTERY SHOW EUROPE 2024

날짜 : June 18 - 20, 2024

장소 : Stuttgart, Germany, Booth D40

The Battery Show Europe is the leading meeting place for the advanced battery and H/EV technology community. Visit us at booth 8-D40 and find out how laser technology can be used in battery production.

주요 제품

Exact Mark 210 TL로 대용량 마킹 비용 절감<

단일 생산 작업에서 최대 30 트레이의 부품을 처리할 수 있는 새로운 자동 레이저 마킹 시스템을 살펴보십시오.

Coherent 채용

다양한 분야의 과학자와 엔지니어로 구성된 Coherent 팀에 합류하여 고객을 위한 맞춤형 솔루션 개발을 통해 가능성의 한계에 끊임없이 도전해 보십시오.

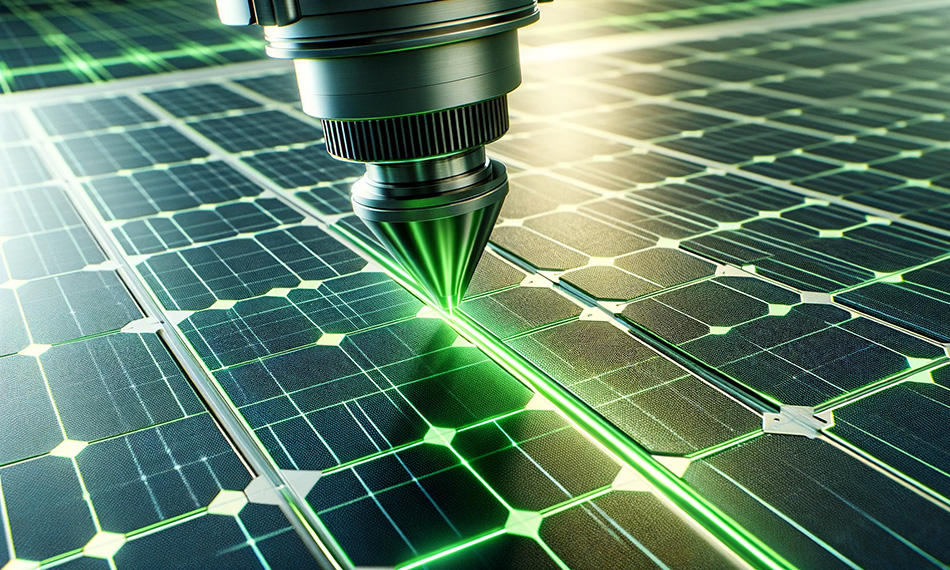

Coherent 연구소

리더십과 혁신적인 레이저 시스템 솔루션을 통해 제조업계가 직면한 가장 까다로운 과제를 해결합니다. Coherent의 전문가들은 매년 2,500건 이상의 프로젝트를 통해 고객을 지원하고 있습니다.